The Challenge: Designing HVAC for Grow Rooms

Mechanical HVAC for grow rooms can be the greatest limiting factor or the greatest opportunity to maximize productivity and profits in the indoor Cannabis Cultivation Industry. Those involved in cannabis HVAC system design, service, and operations are realizing that undersized or oversized systems from inaccurate load calculations for a given room lead to major challenges.

The HVAC system impacts all the parameters that are critical to plant growth. The plant’s health, growth rate, and crop yield all depend on meeting the optimal targets. Optimizing the room or environment must consider ranges for light, humidity, temperature, airflow, water, etc. To maximize the plant’s growth rate and yield, HVAC systems must be able to support cannabis growing humidity range and meet the optimum conditions for all these parameters. The biggest challenge is that these optimal conditions change hour-by-hour, and sometimes even minute-by-minute.

Compared to other HVAC applications (comfort cooling/offices and manufacturing spaces for example), few require as much control and dehumidification as cannabis cultivation and indoor plant environments.

The Solution

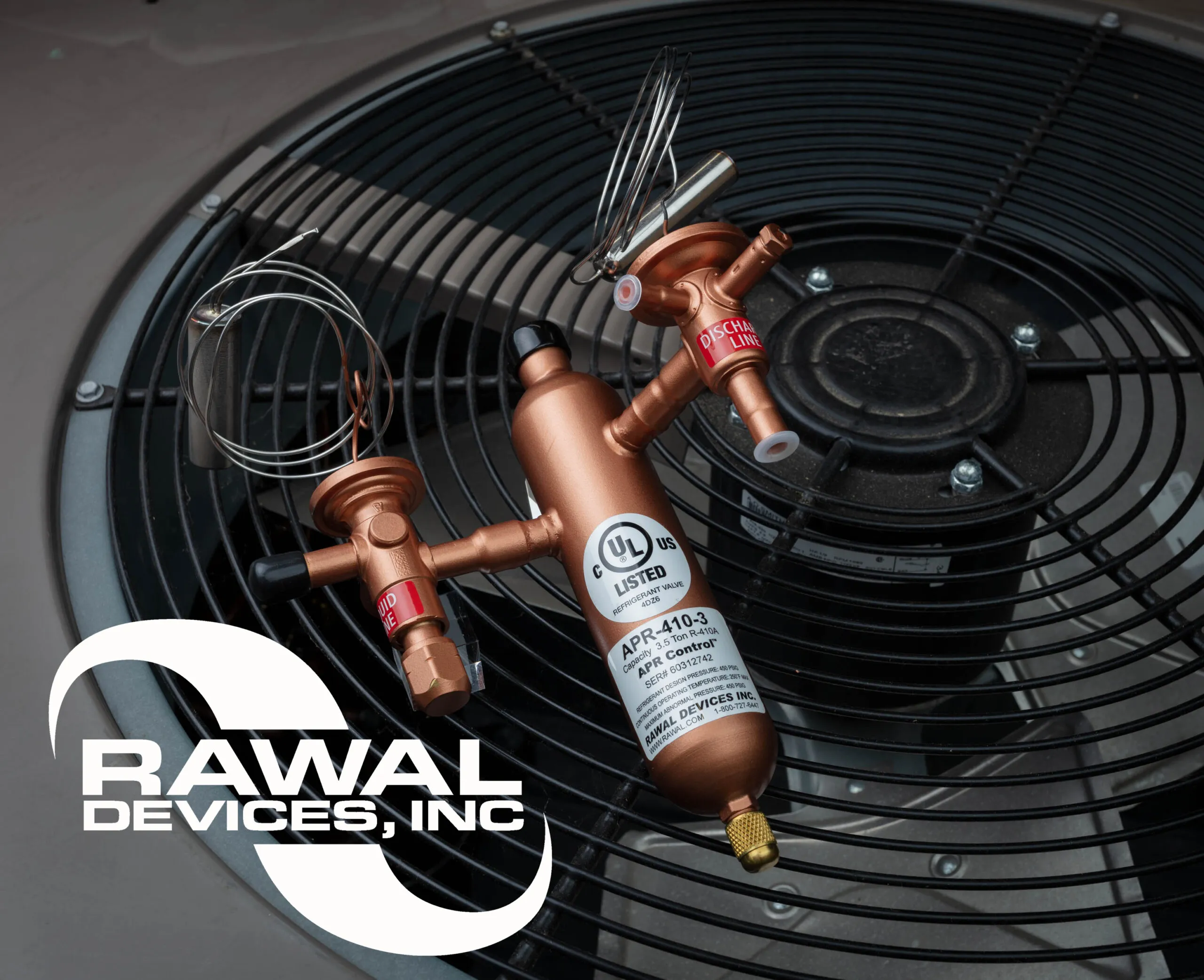

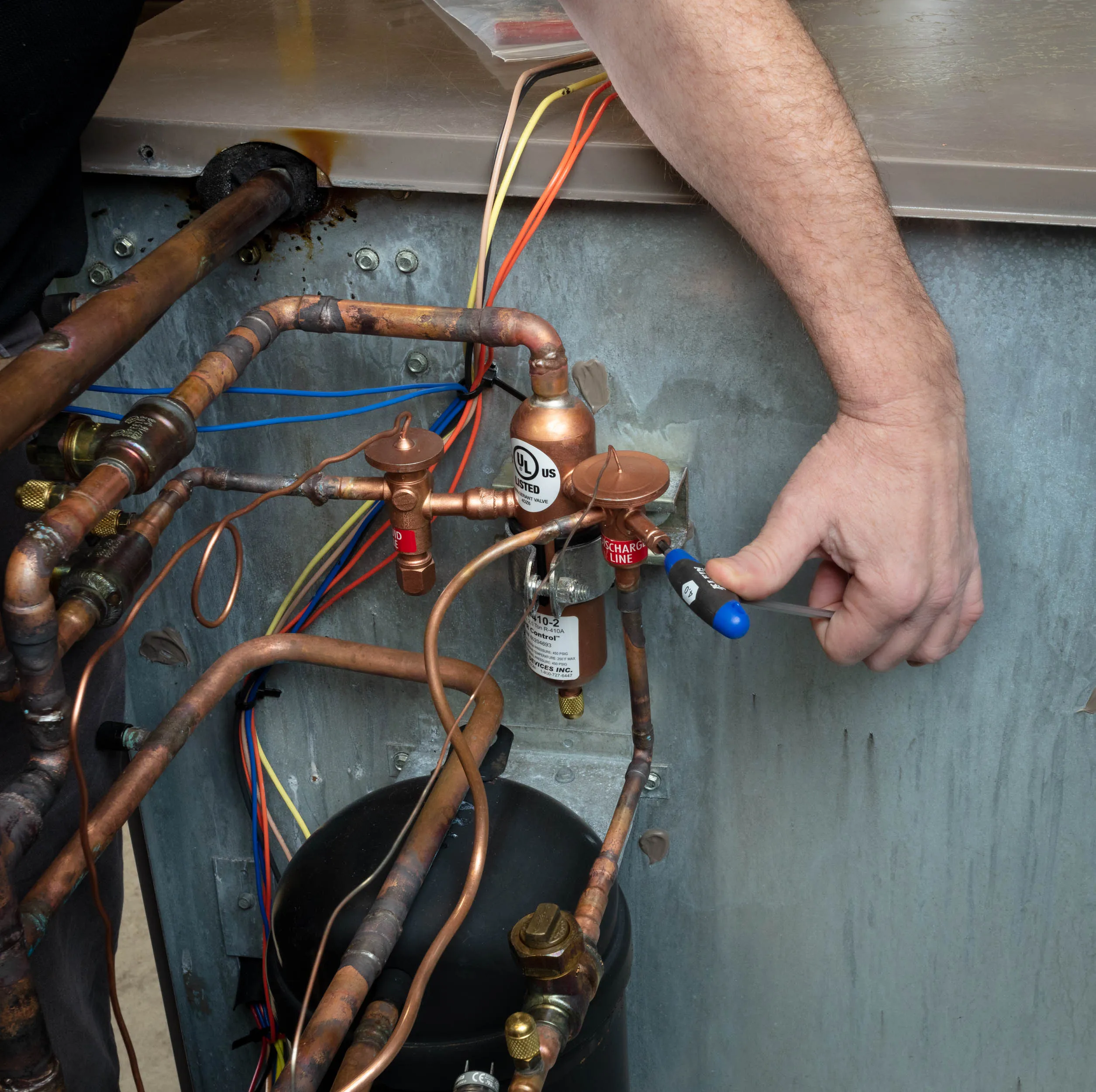

Engineered Solution: The APR Control or APR-E Valve Offers a Unique DX Humidity Control Solution

The APR Control is the perfect, low-cost, temperature and humidity control solution for any cannabis or indoor agriculture HVAC grow room challenges. The APR can benefit system operation on such dynamic spaces, providing exceptional control and ultimately improved product and yield.

Rawal Devices’ modulating technology, both mechanical and electronic, transforms standard systems into variable capacity systems. This is critical for grow rooms.

With the APR’s ability to provide capacity modulation and precision discharge air control, your units will be able to meet ever-changing room criteria. Being able to load match perfectly and proportionally in response to changing optimal cannabis grow room conditions, the APR Control will improve new and existing equipment to produce maximum plant yield and increased grow room profit margins!

Case Studies