It is no secret that a system with the ability to modulate capacity can provide better reliability and fewer operating problems. Without modulation capabilities an oversized system is likely to cause unnecessary stresses on the systems compressor and other vital components.

All air conditioners are oversized by design. Most units are designed for peak load conditions, the hottest day of the year and maximum occupancy. During non-design days your air conditioning discharge air temperature might get a little too cool, resulting in the system not functioning ideally.

During part-load or non-design day conditions or with lowered by airflow, you’re going to have less total heat content across the evaporator coil compared to your compressor capacity. Having enough heat content in the air entering the evaporator is critical to prevent Evaporator Freezing and Liquid Slugging or Floodback.

What causes an evaporator coil to freeze?

As you know, the evaporator coil removes moisture from the entering air. If at any point the evaporator coil temperature (SST – Saturated Suction Temperature) drops below freezing, then all the moisture on the coil begins to freeze – and ice will form.

Evaporator coil freezing is an unfortunate and costly consequence from one of several issues including:

- Dirty Filters

- Lower Airflow by design

- Reduced Temperatures (from thermostats being set too low)

- Mechanical Failures

Icing or frozen evaporator coils may also eventually cause expensive major water damage within the space the system is serving. These consequences can also lead to possible compressor failure!

How can I prevent my evaporator coil from freezing or icing?

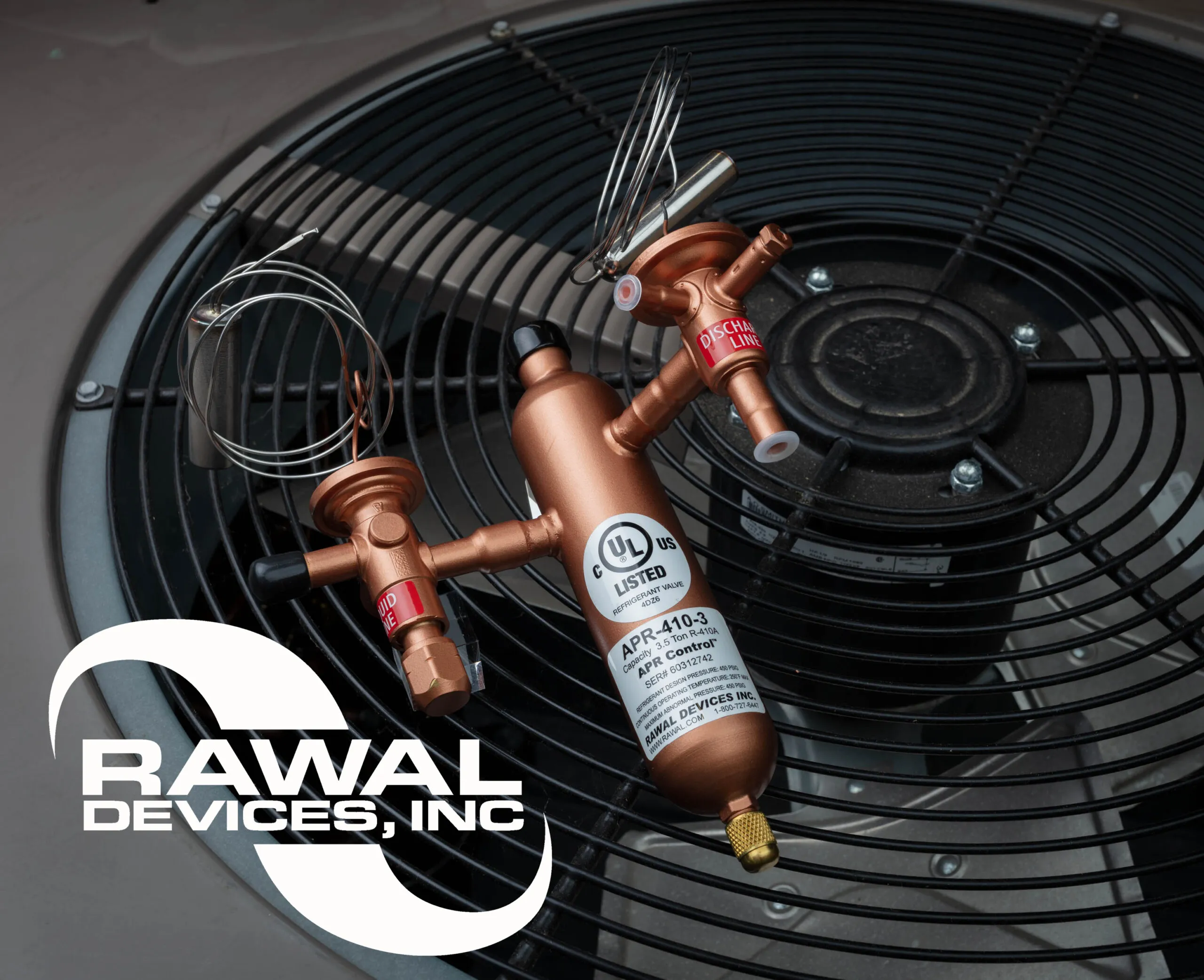

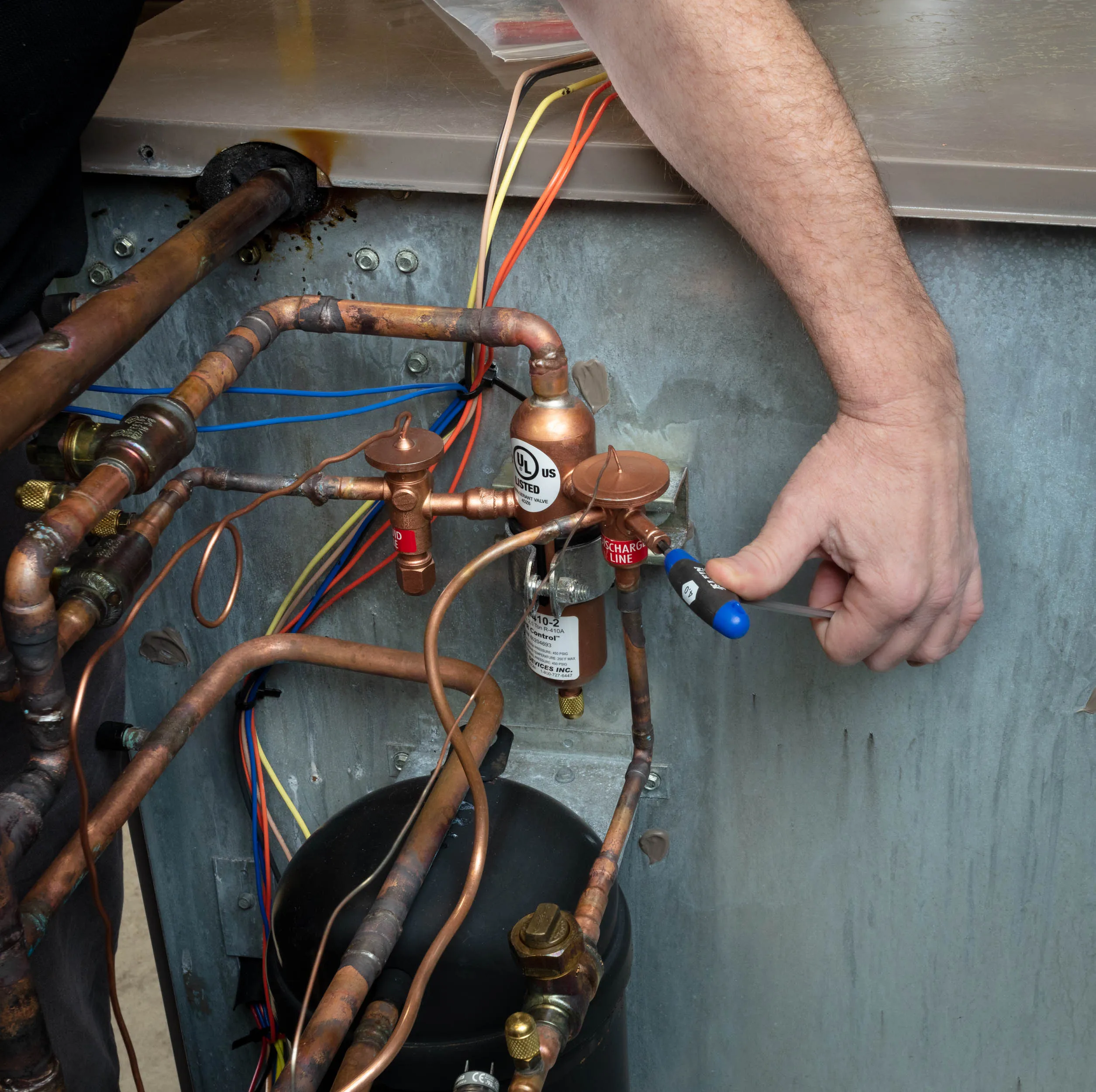

Having capacity control enables the system to compensate for the problems that lead to evaporator coil freezing. The APR Control’s ability to modulate a system’s capacity helps prevent freezing of the evaporator coil by maintaining the suction pressure high enough to never allow the coil temperature to fall below freezing.

Installing the APR Control allows for continued system operation without any major expenses like changing equipment or duct modification.

Why is my system flooding or liquid slugging the compressor?

Anytime there is inadequate heat transfer at the evaporator, the coil will no longer be able to evaporate all the liquid refrigerant as intended. Floodback or Liquid Slugging can occur whenever there is a mechanical failure such as:

- Bad/ Damaged TXV

- Broken Fan/ Inadequate Airflow

- Frozen Evaporator Coil

- Failed Dampers

Flooding or slugging is usually the result of the compressor providing too much cooling capacity for the load in the space or not having enough heat content in the air to evaporate the liquid refrigerant. Compressors are a vapor pump that can’t handle liquid refrigerant. If liquid refrigerant enters the compressor without having boiled into a gas, this could permanently damage the compressor!

How can I prevent liquid slugging or floodback from happening?

The solution is simple, adding the APR Control minimizes the risk of and ultimately prevents liquid floodback or slugging from occurring as a result of the APR’s ability to modulate the system’s capacity.

The APR Control varies the cooling capacity of the evaporator coil by modulating refrigerant flow. During low load or non-design day conditions, the APR Control will only be sending enough refrigerant into the coil that can be fully evaporated.

During mechanical failures, like a broken TXV or loose fan belt, the APR Control diverts vapor into the suction line so that liquid refrigerant never reaches the compressor!

The APR Control is a simple, reliable, and cost-effective solution!

The APR Control’s ability to provide variable capacity control through mechanical means allows your system to match capacity of your equipment to the total heat load across the evaporator coil.

Rawal Devices’ APR Control can eliminate or prevent common problems associated with DX cooling – including eliminating Evaporator Coil Freezing and Liquid Slugging!

As a result, APR Control reduces downtime from labor-intensive service calls and costly warranty issues, make the APR Control a very cost-effective solution for problems occurring on you existing equipment and even on new systems!

Learn More About Maintaining the lifespan of the compressor and system with the APR Control