The introduction of outside air with highly variable load creates the need for variable-capacity systems. APR Control enables the system to match capacity with changing load conditions.

Local and national building codes require ventilation rate minimums to address potential health issues. Coronavirus (in 2020) just being the latest example! Proper ventilation rates contribute to improved indoor air quality, which not only contributes to healthier indoor environments but also improves the productivity of occupants. Most cases of sick building syndrome can be directly traced to inadequate ventilation.

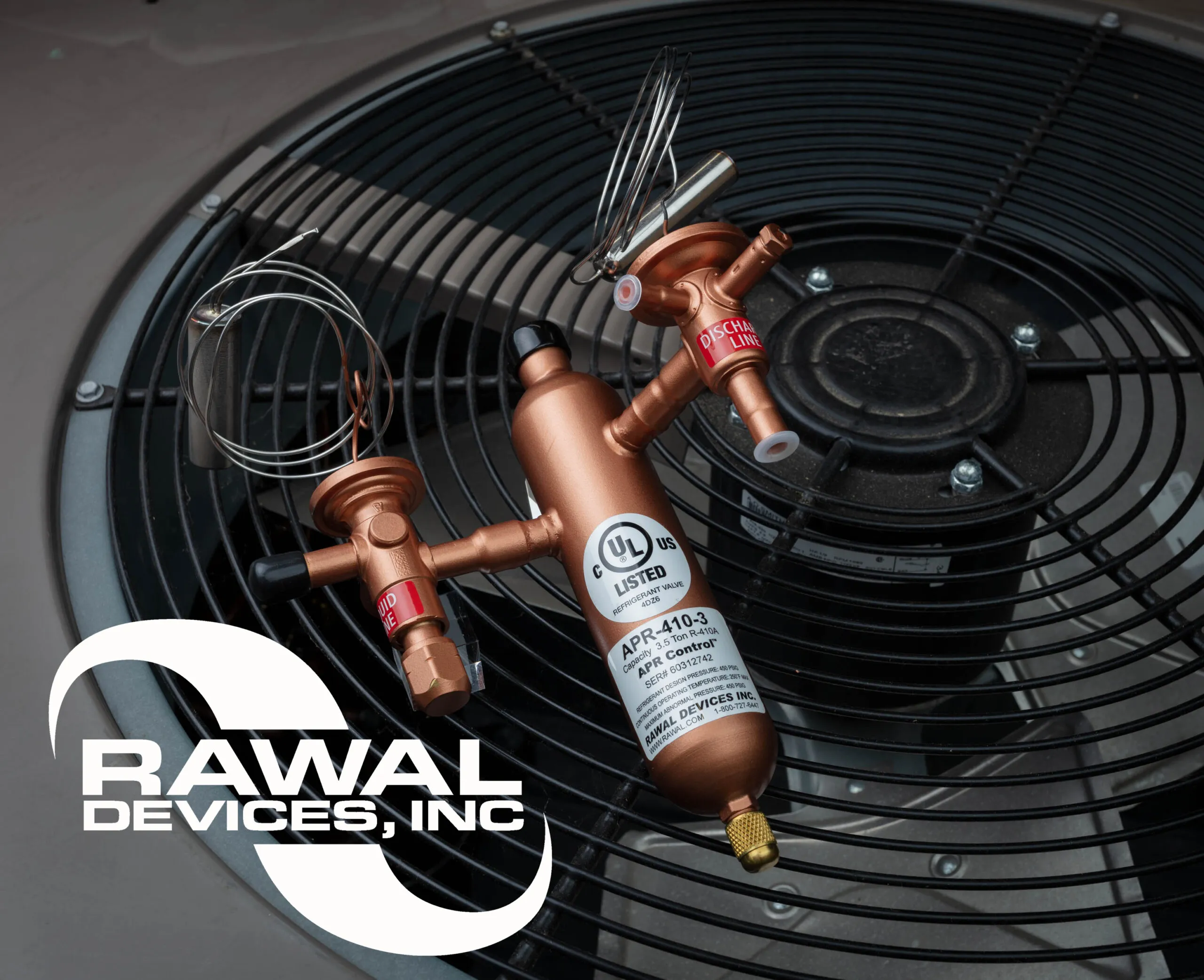

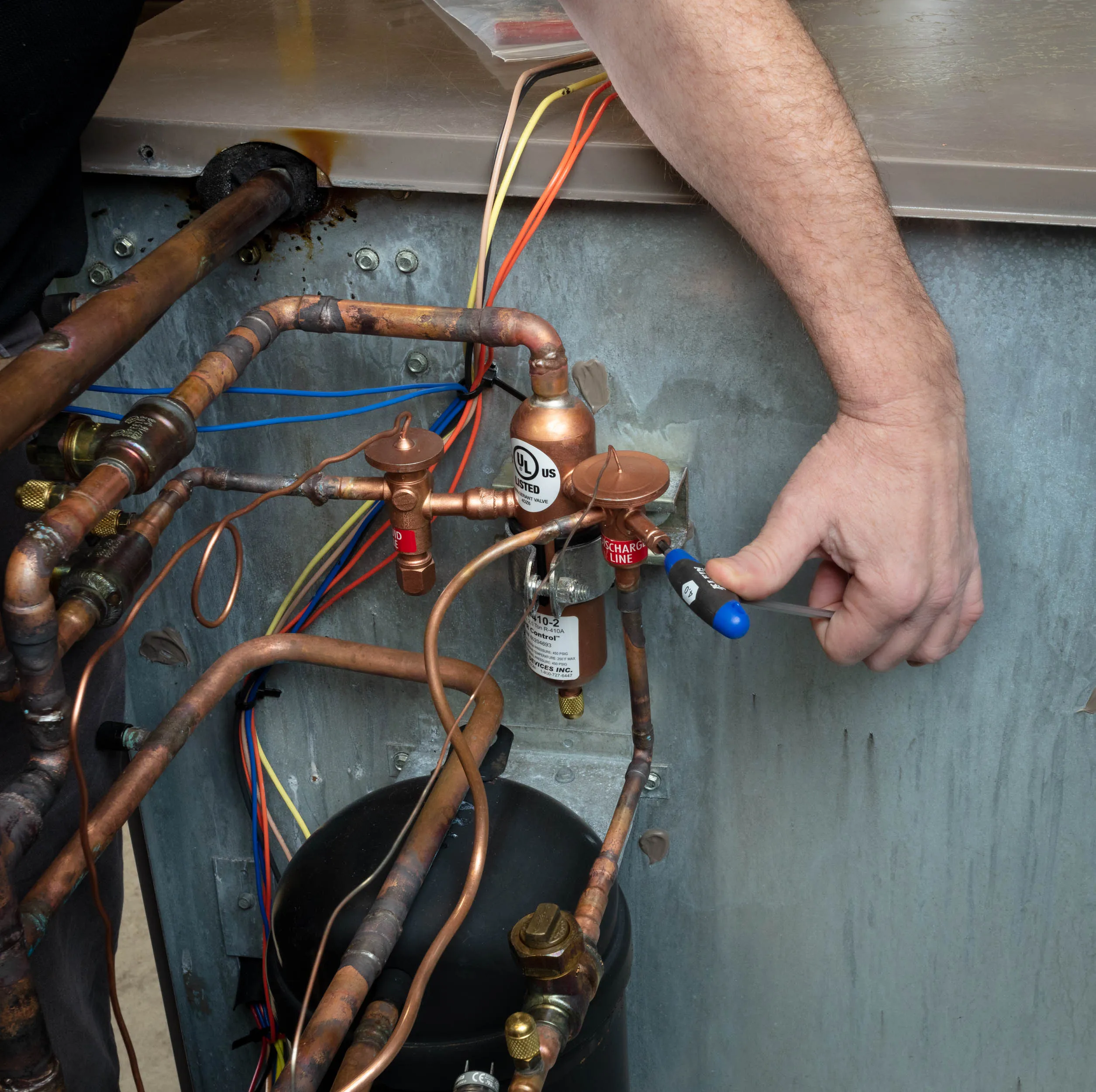

For cost-effective solutions, many engineers and contractors look to the APR Control to give their systems’ the necessary range of load matching; from (up to) 100% Outside Air for Laboratory applications to as much as 40% for Classroom environments and similar ranges for many types of Kitchen Ventilation applications. The APR Control has provided cost-effective solutions for all types of outside air concerns.

Example

A school building in Maryland had a mold growth problem in some of its classrooms. As a result of oversized air conditioning systems and high amounts of outside air (as demanded by then current ventilation codes), the simple thermostatic controls were satisfied too quickly, causing compressor short cycling. The reduced compressor runtime from reduced occupancy resulted in rising humidity levels.

Following installation of the model APR-410-2 Control (~2.5 tons capacity modulation for R- 410A), the 4-ton systems were given the ability to operate down to a capacity as low as 1.5 tons, extending the runtime significantly. This reduced humidity in the space that was the primary cause of the mold growth. The reduction of humidity was achieved by allowing air to continue passing across the cold evaporator coil without quickly satisfying the thermostat!

Case Studies