Applying the APR Control to new and existing systems requires proper evaluation and selection.

These criteria include:

- System capacity – both total and staging

- System configuration – single or multiple circuits

- System type – package or split system

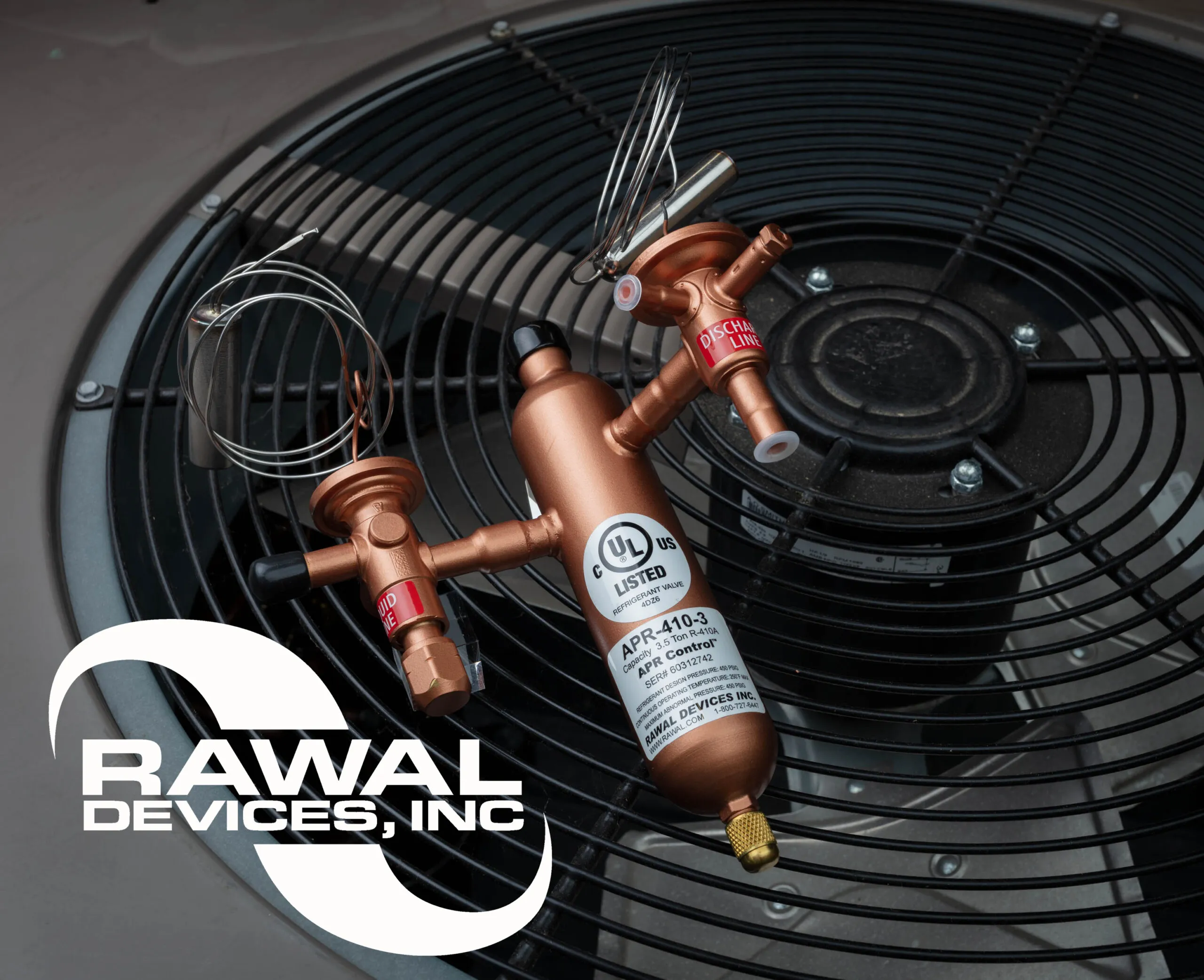

- Refrigeration type – R-22, R-410a, R-407c and others for which we can provide capacity control and modulation

- Specific to split systems – suction line sizing and routing with specific attention to suction gas velocity for oil entrainment back to the compressor at low load conditions

We are pleased to assist both new and long-term customers with selection of the best APR Control model (percentage of modulation) for their particular application. Most systems that employ a low minimum of outside air (ventilation air) will benefit from up to 80% modulation on a simple single-stage system, or even on the lead stage/circuit of a simple multiple-stage system.

Holistic Analysis

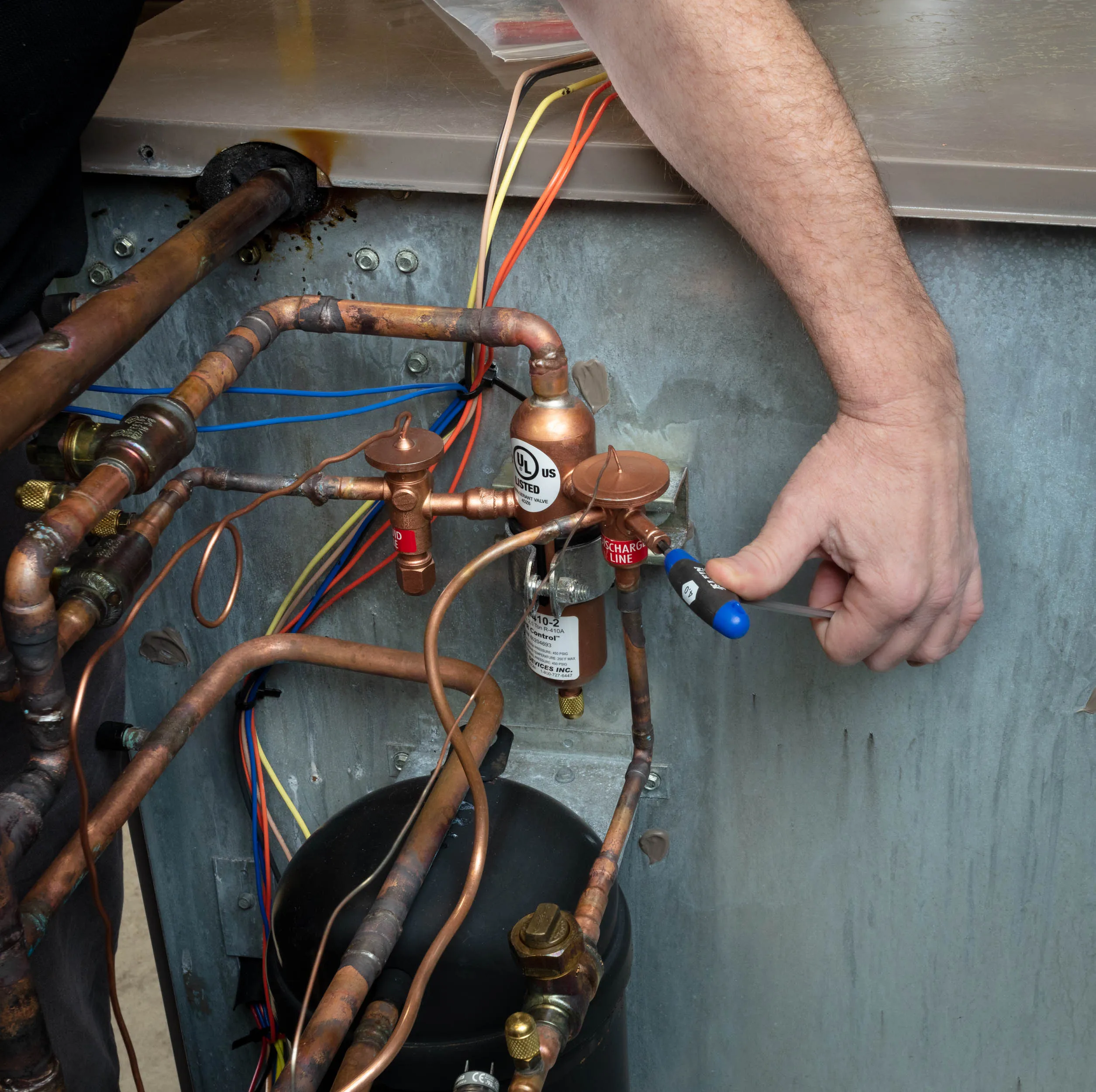

When system application deviates from the base standard, which is why we often get called upon, Rawal Devices engineers look at the whole application, including outside air introduction, space usage, internal base load of the space, and (on existing systems) what is the condition of the space and how is the unit currently operating (cycle timing/runtimes). In addition, we also review how the controls impact system runtime and performance, the availability of upgrading controls, or adding some small amount of reheat where it may be necessary.

Please note that you must take staging and circuiting into account. This means that a 10-ton system is often the result of two 5-ton stages, and a single APR Control installed on the lead circuit/stage might be sufficient for the needs of the system. So selection needs to be based on the 5-ton stage and all the factors that might impact the operation of that stage.

Case Studies