HVAC callbacks and warranty issues are an enormous problem and headache for HVACR contractors and service technicians. With the addition of the APR Control, you can eliminate callbacks on new equipment and improve performance of older/in-place equipment, saving you (and your customer) both time and money!

Contractors following best practices conducting start-up and commissioning on newly installed equipment (to ensure proper operation that meets design) will find most systems satisfy the needs of the space. Callbacks occur and though not necessarily a result of anyone’s failure to install the equipment according to design, convincing your customer can be difficult…

Common Issues for HVAC Callbacks

While the equipment selection for a building’s needs may have been appropriate at the time of design and installation, unforeseen changes to the space and conditions can occur, resulting in a wide range of mechanical issues/equipment issues and system alarms.

- High Humidity Alarms

- Short Cycle Alarm Lockouts

- Nuisance Trip-outs

- Coil Freezing

- Reduced Airflow/ Low DA Temperatures

- Blocked Returns/ Low Suction Alarms

- Component Failure

All these service issues can be indications that the system is oversized and can contribute to system failure or safeties being triggered. All DX systems are designed for what is commonly referred to as a “design day” aka the maximum cooling load expected in the interior space. These “design days” rarely occur, meaning that any properly designed system may appear oversized – ultimately providing too much cooling capacity for the indoor space.

Oversized AC Systems

Having an oversized system can lead to any number of system design and installation challenges causing damage to the equipment, the interior space, and ultimately lead to numerous customer complaints. As service contractors you are almost guaranteed to see these problems arise on both new and in-place equipment.

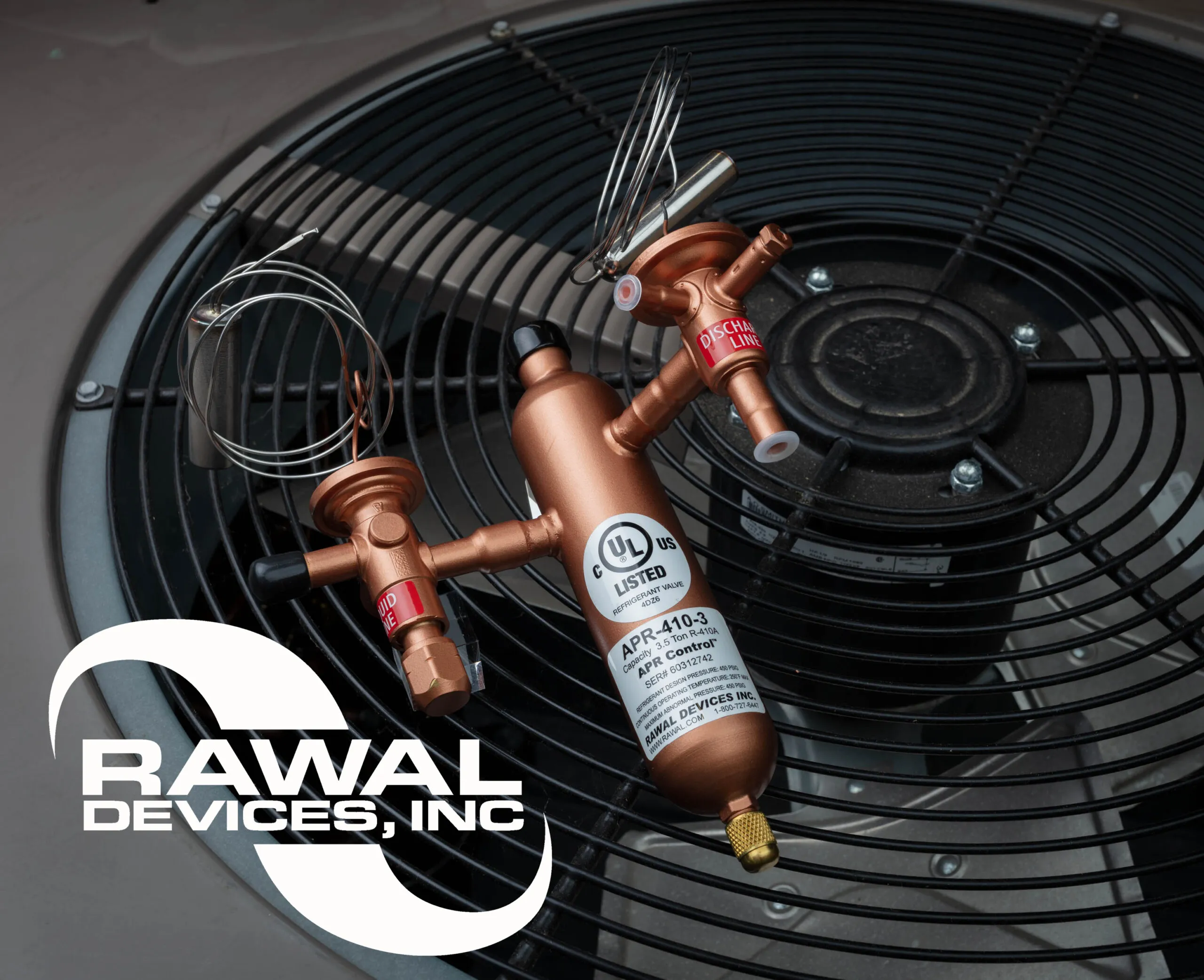

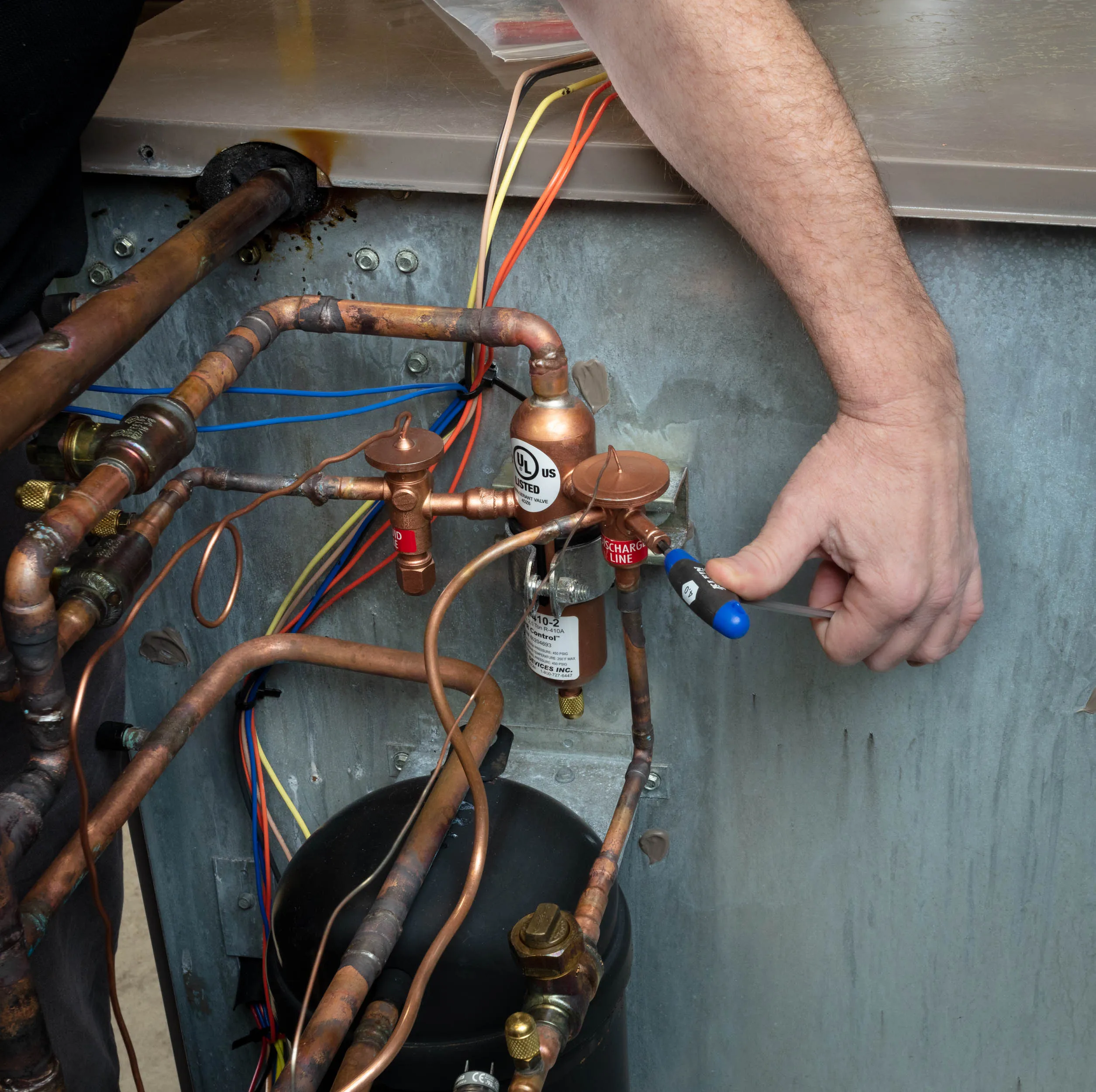

The most simple, reliable, and cost-effective solution is the APR Control and its ability to provide capacity modulation. The APR Control can reduce or eliminate risk of these service issues because it modulates system capacity to match the cooling load in a space.

Avoid the Constant HVAC Callbacks: Benefits of APR Control

The APR Control:

- Reduces Short Cycling

- Eliminates High Humidity

- Protects Against Coil Freezing

- Prevents Liquid Floodback

- Offers Passive Compressor Protection

The APR Control’s load matching capability extends the runtime to keep the compressor active for a longer runtime and better dehumidification cycle. The APR Control also provides consistent discharge air temperatures like those necessary for VAV, VVT, or make-up-air systems – All while reducing the short cycling.

The APR Control prevents freezing of the evaporator coil by keeping the temperature of the coil above freezing. As you know, if the evaporator coil temperature is below freezing for any length of time, ice will form and cause unit downtime and potentially catastrophic failure! The APR prevents disruptions in service while extending the lifespan of your system, avoiding excessive mechanical wear.

From new equipment to 20+ year old equipment, the APR will improve system performance and life expectancy of any DX AC equipment. Having the APR Control as a readily available solution will greatly reduce any problems that will lead to call backs or warranty visits that cost contractors money out of their pocket – taking away from profit. Warranty reserve protection is a major benefit for Contractors and Service Technicians, saving the budget from call backs and repairs on new installations, especially!