HVAC preventative maintenance and the APR Control

Recommending the APR Control during preventative maintenance to maximize efficiency, performance, and lifecycle!

We have officially entered Spring, which means it’s cooling season for many parts of the country. Accordingly, contractors and service technicians are performing routine preventative maintenance on the HVAC equipment for your customers.

Why is HVAC Preventative Maintenance Important?

Preventative maintenance (PM) is performed to identify equipment issues to bring the customer’s attention to concerns, making certain that the system will work when they need it. It allows the technician to predict, identify and correct a variety of issues that would otherwise go unnoticed until it becomes an emergency. At that point it could be a much bigger problem. Now is the time to catch these problems before they become major headaches from repeat service calls (especially during inconvenient times, AKA your weekends).

During PM visits, as technicians, you will have more time to listen to the customers about the general comfort level during operation before hearing how hot it is once the unit has already failed. Techs will likely hear about high humidity issues from last year (being uncomfortable in the space), that you may not have heard then but are now aware of. Preventative maintenance provides the opportunity to diagnose the system a bit more thoroughly than you otherwise would during an emergency service call where the problem is immediate and appears obvious.

During preventative maintenance a technician may notice a variety of technical issues:

- Compressor short cycling

- Liquid flood back from low loads (Red Flag)

- Overcooling of the space

- Low DA Temp/ Freezing of Evaporator Coil

- High humidity in the space

- Multiple compressor changes

It is important that you notice these issues while the equipment is still running before the inevitable equipment failure occurs.

How does the APR Control Solve Common Preventative Maintenance Challenges?

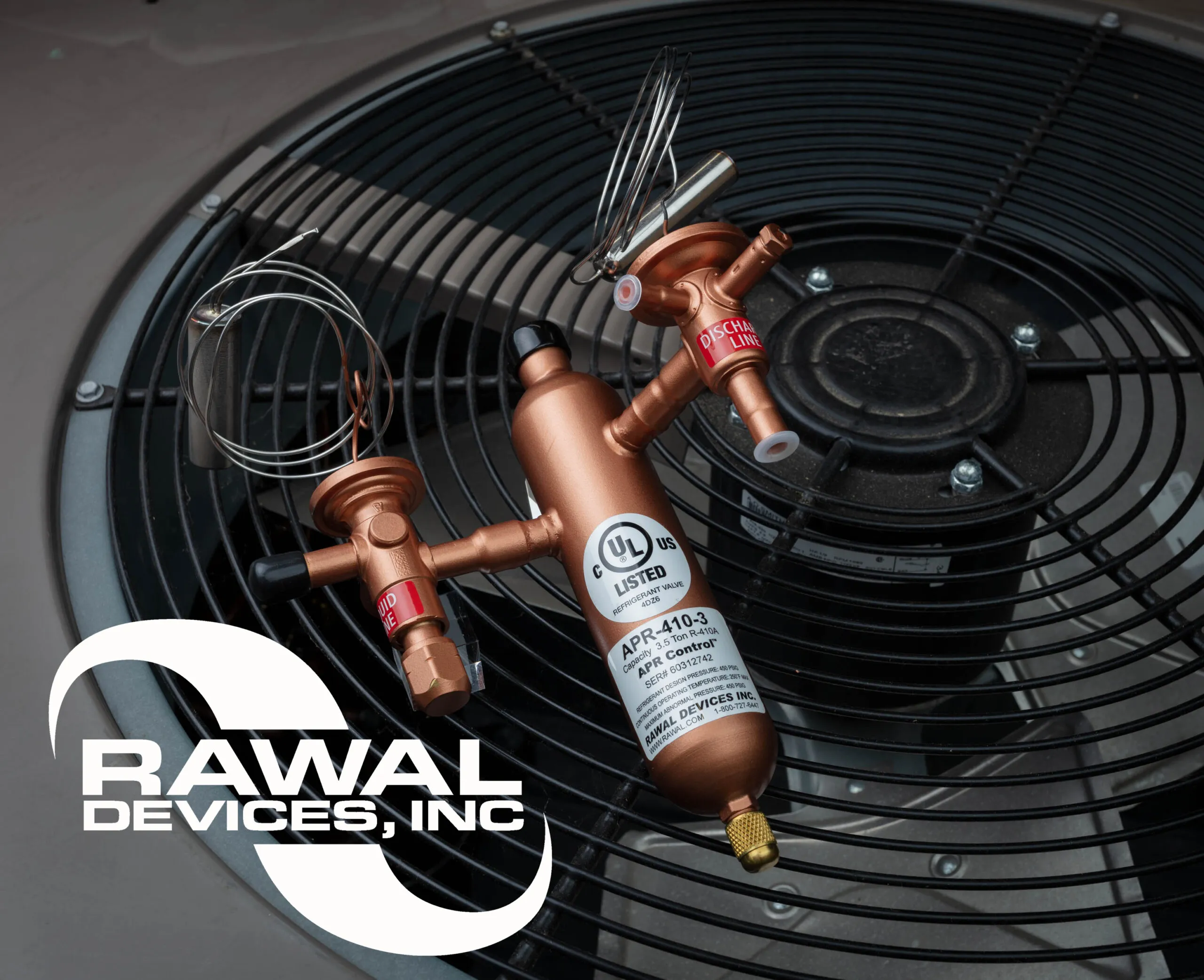

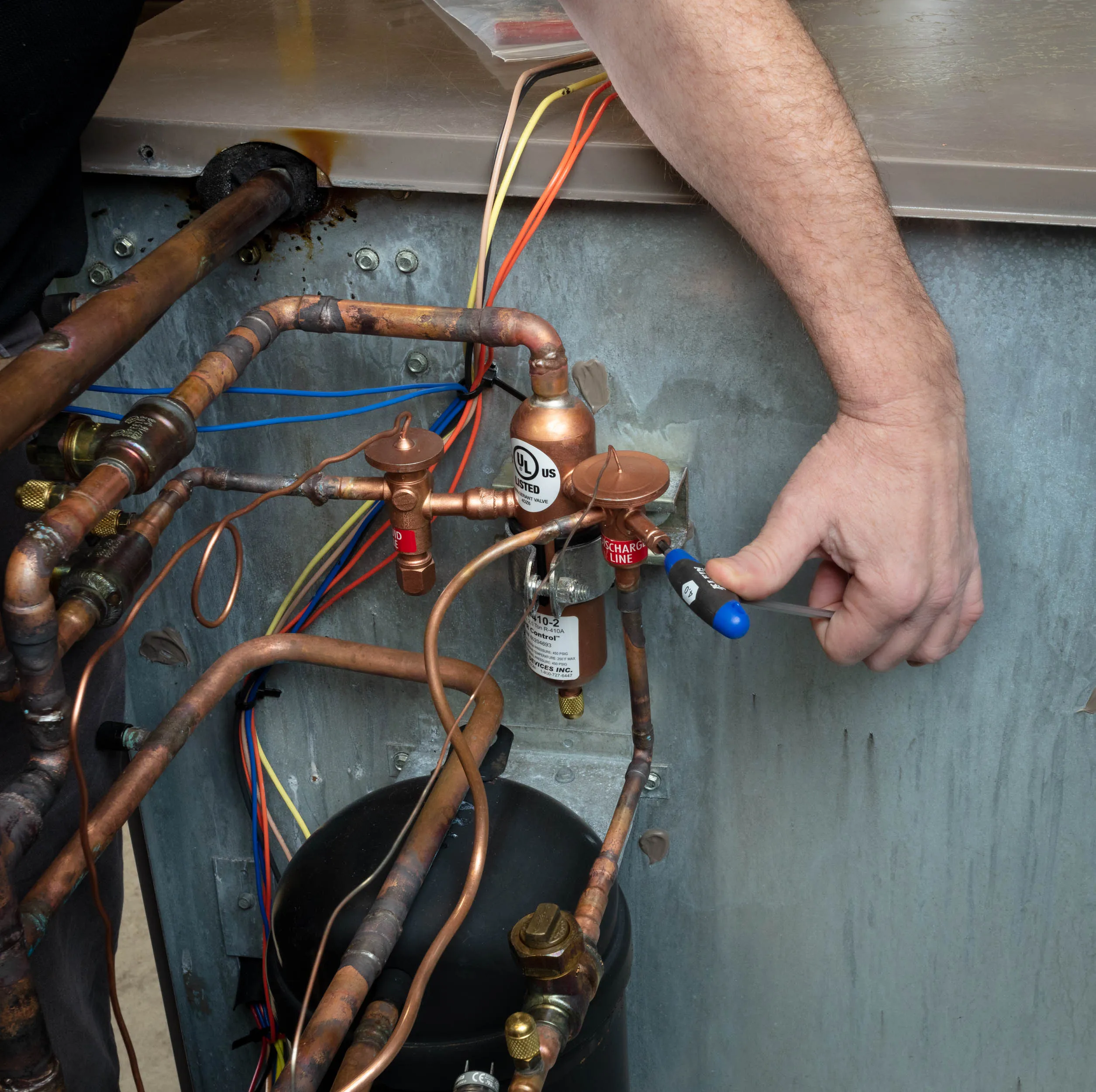

The addition of the APR Control could be one of the best preventative solutions you, as a contractor or service technician, can offer to address problems before they become ongoing customer complaints.

The APR Control provides continuous capacity modulation for any standard DX system, properly matching the system capacity to the ever-changing load conditions and space requirements, solving many of the issues that commonly arise among oversized AC systems (listed above).

Achieving true load-matching capabilities with the APR increases compressor runtimes to eliminate short cycling. Extended run-times keep the evaporator coil active longer, resulting in improved latent cooling performance for greater comfort and indoor air quality levels.

Additionally, adding the APR Control offers capacity modulation that makes the system capable of responding to and eliminating the impacts of low airflow (overcooling the space and evaporator freeze-ups).

Your customers will appreciate your approach in proactively recommending the APR Control solution during preventative maintenance to address any issues now and avoid interruptions in their daily operations going forward.

The APR Control is a cost-effective and reliable solution that can be field installed on virtually any existing DX equipment!

Learn more about how the APR Control enhances equipment performance and reliability!