The Challenge

Sensitive materials, processes, and machinery require low humidity and stable temperatures. High humidity can destroy materials and affect production. Specialized applications often require the HVAC system to maintain tight space temperature and humidity requirements.

The Solution

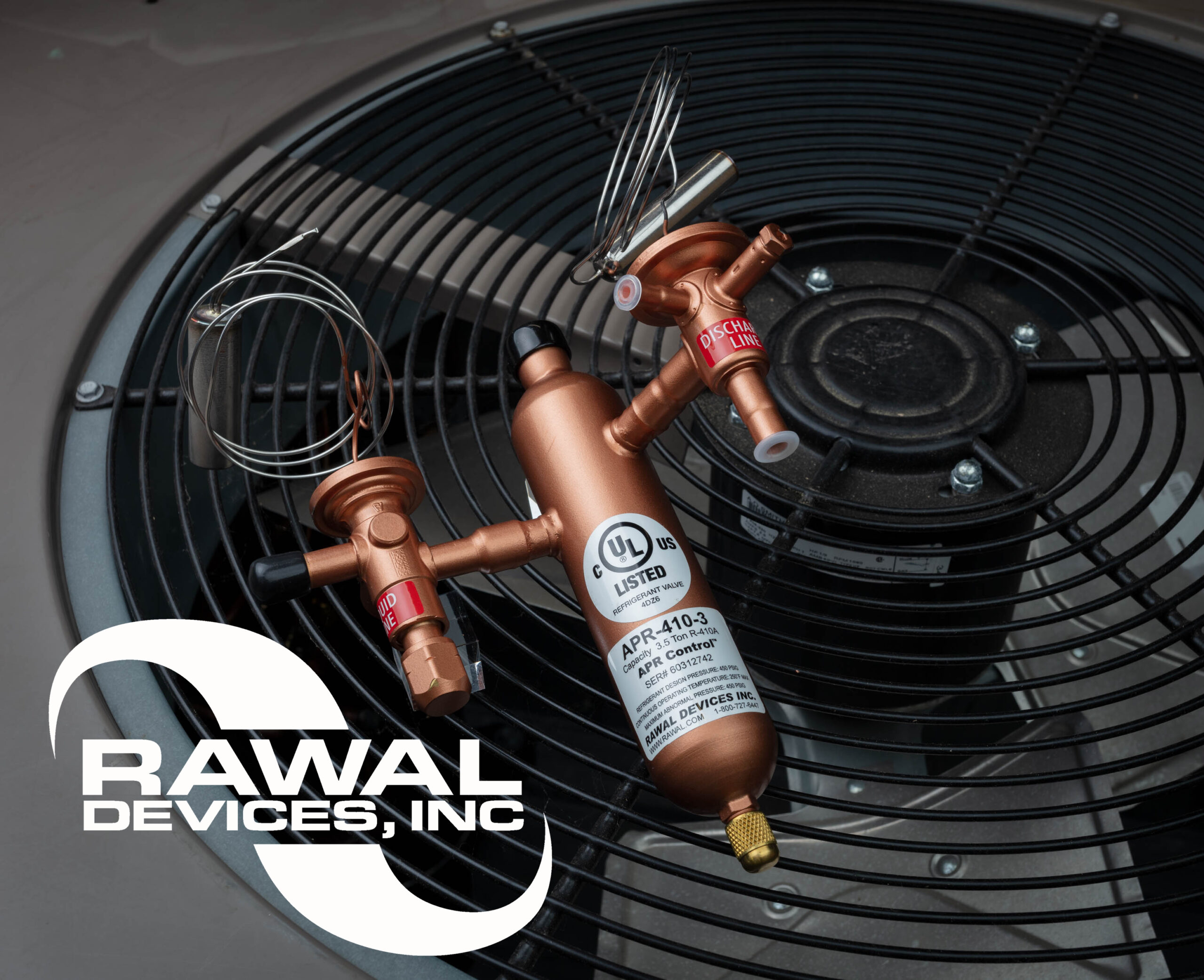

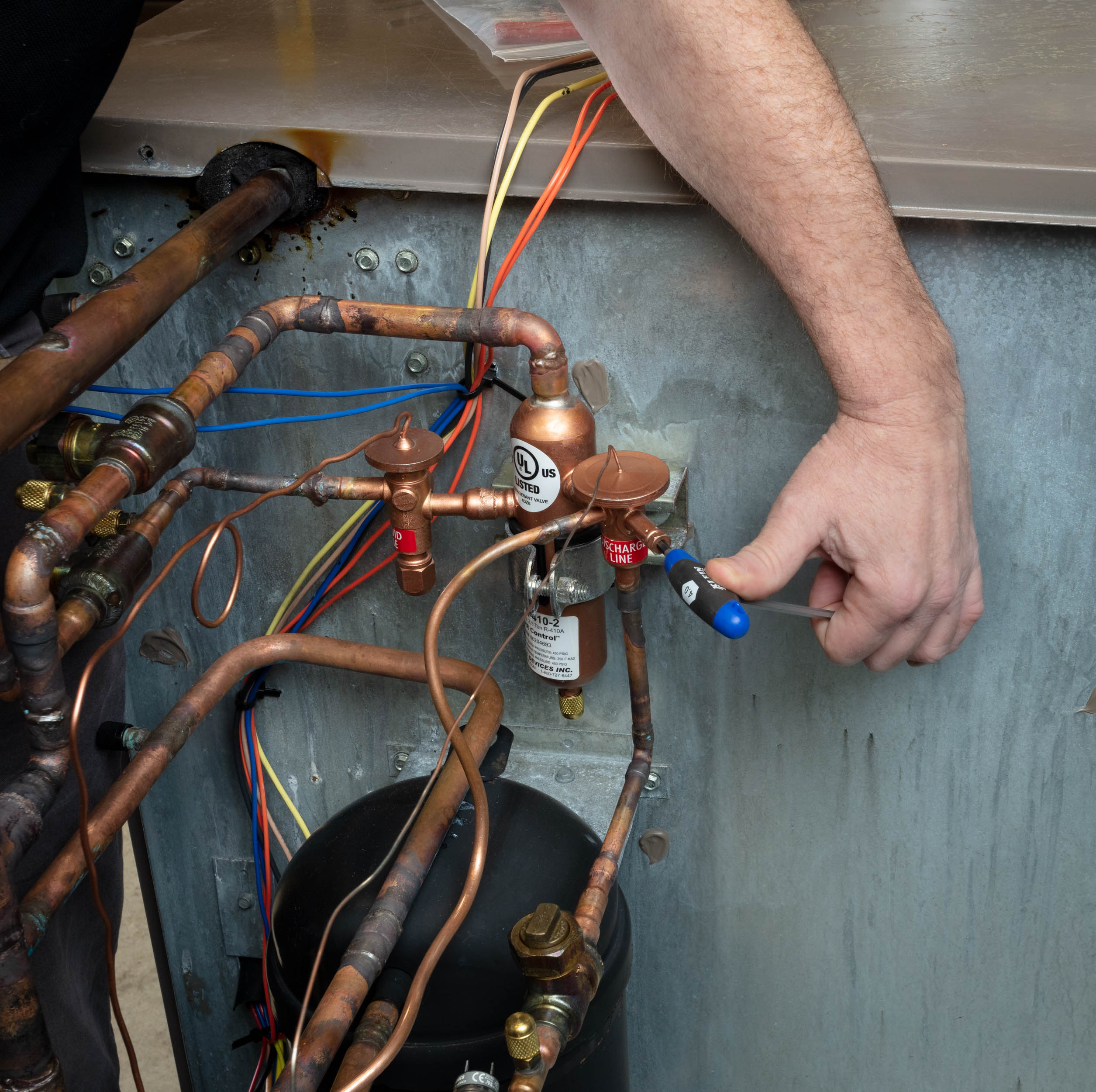

The Rawal APR Control virtually eliminates cycling, reduces relative humidity levels, and continuously maintains the discharge air below the dew point requirements for the space. Rawal Devices engineers can assist in helping you create systems that will reduce operating costs and improve productivity through increased worker comfort.

Case Studies

Angiotech electronic valve test / performance

Solving excessive humidity in a race car parts manufacturer test lab environment