How does the APR Control work?

What is the APR Control®?

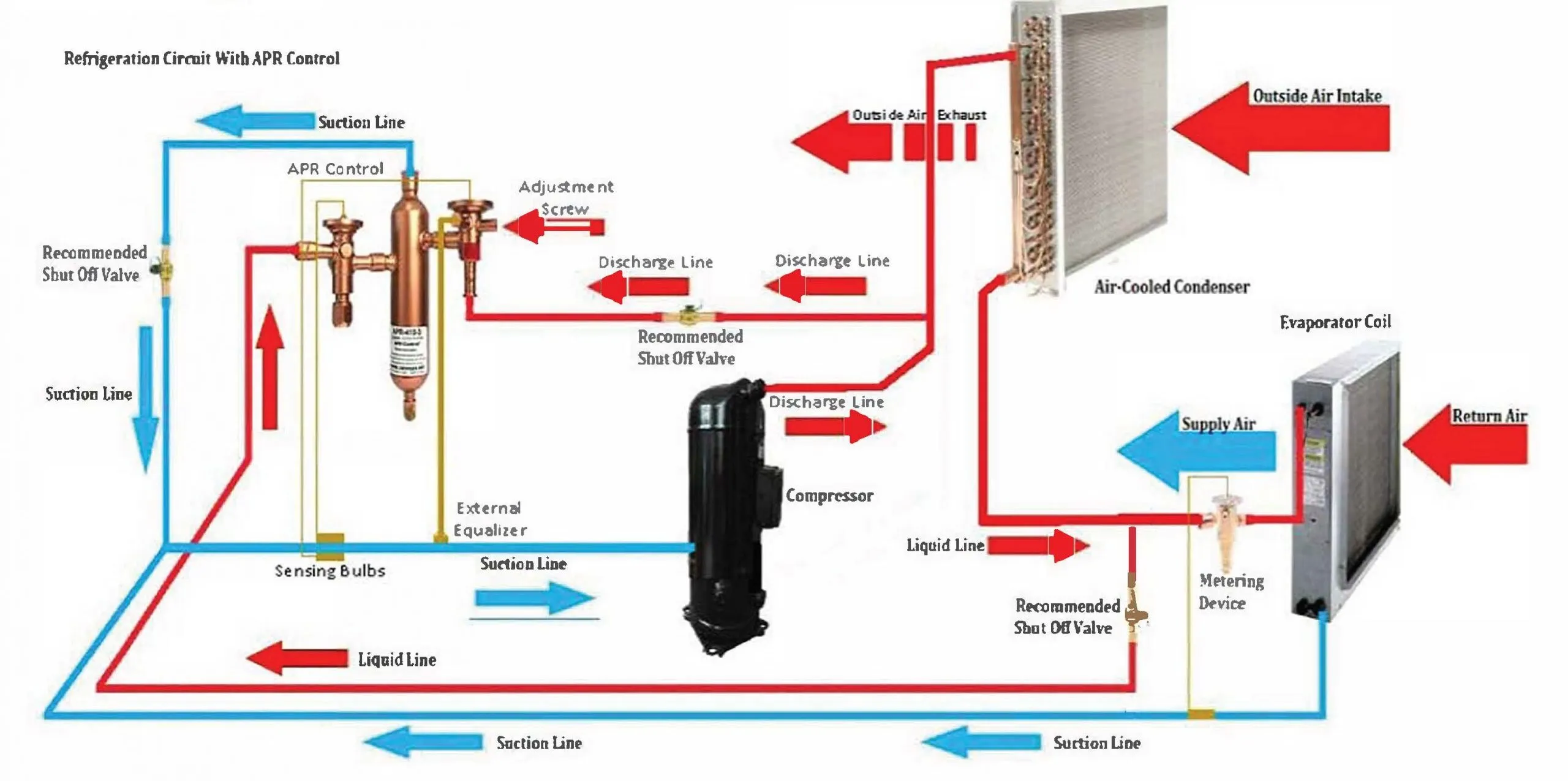

The APR is a capacity-control device that modulates a system’s air conditioning or refrigeration capacity to match variations occurring in the BTU quantity of the existing load.

Operational Description:

The device accomplishes continuous capacity modulation by reacting to the heat content of the system return air, which changes the pressure of the suction gas. Using the APR Control’s compression ratio reduction valve, the APR Control then diverts a portion of the discharge refrigerant from the compressor through the device’s desuperheating chamber and into the suction inlet of the compressor.

The discharge refrigerant gas enters the desuperheating chamber at an angle creating a circular refrigerant path, wiping the walls of the chamber and giving up excess system heat. The gas then travels up the “mixed gas lift tube,” losing energy as it returns to the system’s compressor suction inlet. The increase in suction pressure resulting from the discharge refrigerant and suction gas mix reduces the compression differential in the compressor, causing a decrease in required compressor horsepower and therefore a decrease in required power consumption.

Through the evaporator coil, the APR Control senses the enthalpy of the return air. A reduction in the enthalpy of the return air causes a drop in coil temperature that causes a drop in the suction pressure. This triggers instant response in the APR Control’s compression ratio reduction valve and causes some of the compressor discharge gas through the APR Control desuperheating chamber to the compressor suction return. This results in a decrease in refrigerant to the condenser coil and ultimately less liquid refrigerant to the evaporator coil.

At the evaporator (in an R-410a system specifically), the APR Control attempts to hold the DX coil at a setpoint of 118psi (field adjustable, when required) by changing the rate of flow of liquid refrigerant into the DX coil and adjusting the dehumidification window of the evaporator coil. Simultaneously, the difference in system BTU capacity and the current BTU load is continually being diverted in the form of discharge refrigerant through the APR Control’s desuperheating chamber and into the suction line at the compressor.

The overall effect is a reduction in cooling capacity of the DX coil corresponding to the reduction in the load. Most importantly, the APR Control will not decrease the maximum or designed capacity of the system when it is needed as system pressures will (should) remain above the APR Control’s settings, causing the APR Control to be out of circuit interaction.