Protect your designs from the things you can’t control

Rawal APR Control is a variable-capacity solution for new & existing DX systems in a wide range of facilities and applications

-

Improve performance of DX systems operating outside design parameters

-

Reduce risk from unknown variables in your load calculations

-

Help your contractor relationships - recommend an easy to install aftermarket solution

Rawal APR Control:

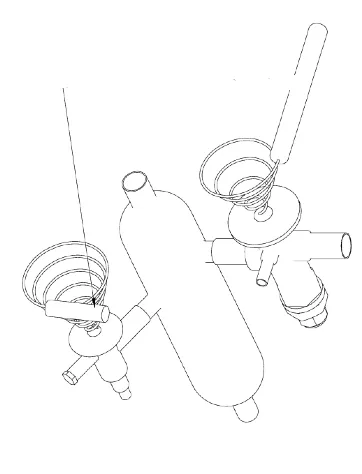

Modify any DX system to operate as a modulating variable capacity system

Rawal APR Control is a variable capacity enhancement for new and existing DX (direct expansion) systems in a wide range of commercial and industrial facilities and applications that helps provide:

- Tight temperature control

- Better humidity control

- Improved high-percentage outside air

- System protection and reduced operational downtime

New technologies may not be right for every situation

New technologies like variable speed HVAC give you new ways to serve your customers. But they’re not right in every situation, can cost more, and may not be in-stock. Rawal APR Control is often easier to install and gets the job done right:

- Repair existing in-place equipment

- Avoid disagreements from call-backs and warranty issues

- Maintain lasting relationships and secure future opportunities by keeping your projects within budget

Simplify the equipment selection process

Accommodate load variability and changing criteria

-

Satisfy the customer’s desire for versatile HVAC equipment to accommodate future expansion

-

Reduce risk when selecting equipment for spaces with unknown variables

Avoid high humidity challenges in any application

Provide capacity modulation to extend compressor runtime

-

Eliminate short cycling to keep the evaporator coil active

-

Provide true load-matching performance with up to 80% turndown

Protect Against:

-

High humidity

-

Temperature fluctuation

-

Excessive compressor cycling

-

Evaporator freezing/liquid flood-back on VAV applications

-

Unconditioned fresh air for ventilation requirements

Provide precision discharge air control

Optimize your HVAC equipment with less effort

-

Meet tight temperature and humidity requirements in specialized applications (Dew Point Control)

-

Achieve discharge air control within 1 degree deviation from temperature setpoint with the APR-E

New design & retrofit solution

- New codes demand increased ventilation and fresh air

-

Provides variable capacity to standard DX units that weren’t originally designed for custom applications

-

Matches system’s capacity to meet new and ongoing occupancy restrictions

- Value engineering option

-

Lower up-front costs without sacrificing performance

-

Ideal for projects with lead-time or budget constraints

For Key Benefits

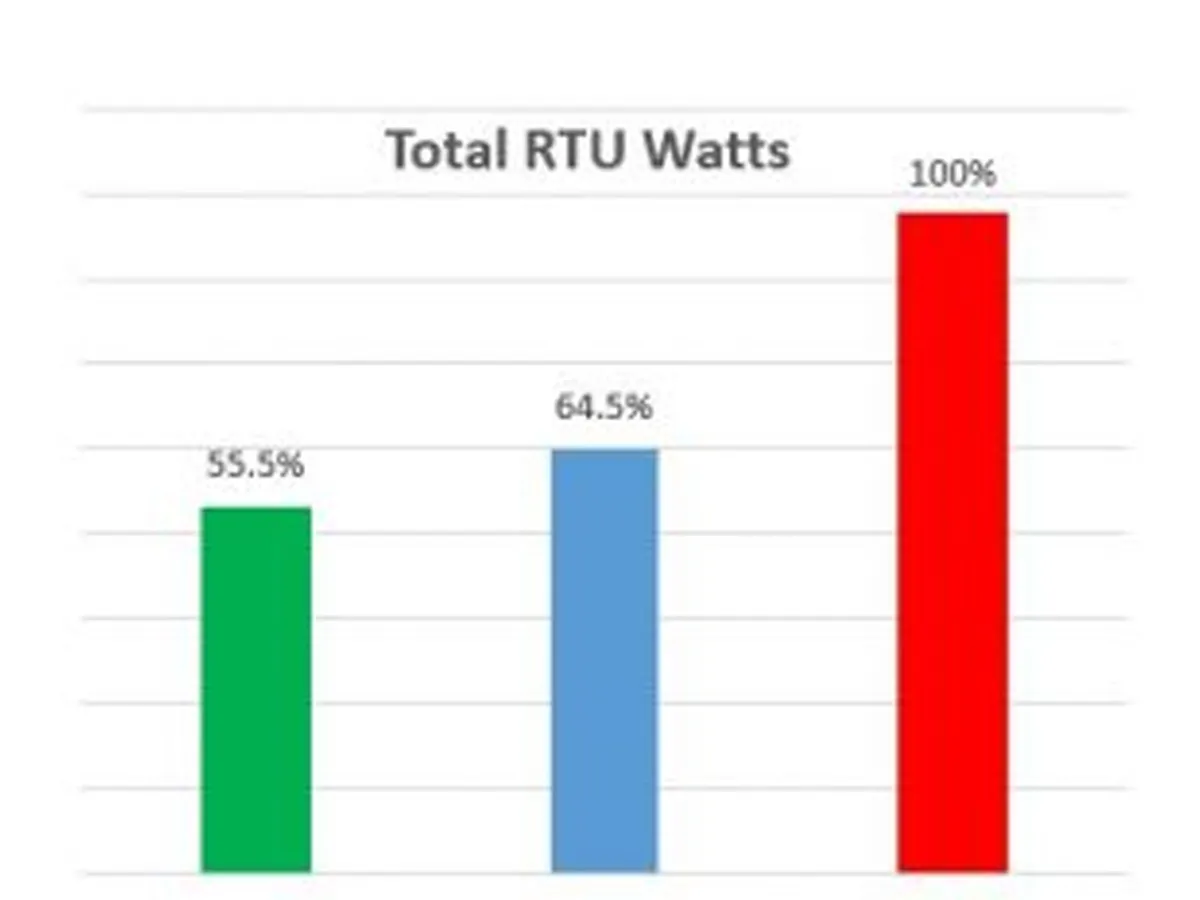

Meeting & Exceeding Standard Equipment Energy Efficiency

- Energy Efficiency Engineers Improve your customer’s HVAC Energy Performance

-

Saves power by reducing lift of compressor

-

Lowers operating costs by optimizing the HVAC system

- OEMs Trusted and installed by major U.S. Manufacturers

-

Major OEMs offer the APR Control as a factory-installed modification, or for field installation when their systems require retrofit upgrades or service

-

Manufacturers use Rawal instead of FIOPS (factory-installed options) where accelerated delivery is required

-

Standardize designs across different geographic regions

-

Units with APR Control have the versatility to serve any environment

For Key Benefits

Build in success from the start

Create satisfied customers and contractors

-

Help the contractor deliver a properly performing system with less stress, per your design

-

Reduce call-backs and preserve warranty budgets, so contractors are more likely to install it than other options

Improve HVAC system energy performance & lower operating costs

-

Save power by reducing lift of compressor to operate at a lower kW consumption

-

Lower operating costs by reducing fan motor speed with minimal risk

-

Reduce or eliminates the need for costly reheat of all types

For Trusted Solution

Trusted and installed by major U.S. manufacturers

-

Major OEMs offer the APR Control as a factory-installed modification, or for field installation when their systems require retrofit upgrades or service

-

Manufacturers use Rawal as a standard component in select equipment lines

For Trusted Solution

Addition of the APR helps equipment to satisfy local codes in any geographic region

-

Standardize designs across different climates

-

Units with APR Control have the versatility to serve any environment

HVAC Design Engineer Resources

APR Control for Ventilation & Fresh Air

-

APR Control Benefits to the Design Engineer

-

APR Control Advantages Over Hot Gas Bypass

When it was introduced to the HVAC industry 30 years ago, the closest comparable reference to the APR Control has been that it is similar to hot gas bypass. However, the APR Control is NOT hot gas bypass! Learn more about the advantages of the APR Control and how it is energy code compliant throughout the HVAC industry.