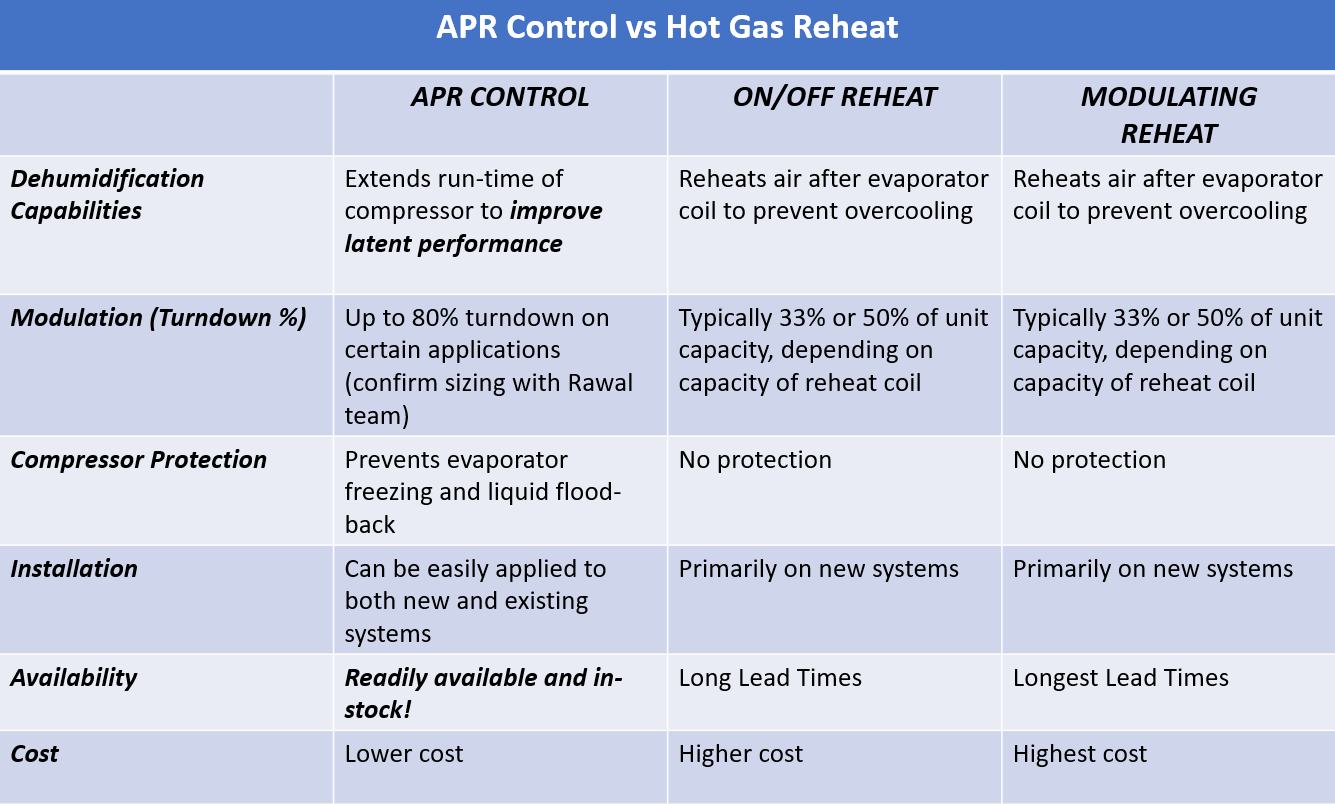

Have you recently had issues with extensive lead times on hot gas reheat (HGRH) units to the point where it will delay your project? If your answer is yes, we can assure you that you’re not alone! We have a solution for you; the readily available APR Control is considered an excellent solution to Hot Gas Reheat that won’t extend the project timeline.

Rawal Devices understands there are a multitude of reasons why customers request a system with Hot Gas Reheat (HGRH); such as the need for additional dehumidification capabilities that off the shelf equipment cannot provide, and the ability to meet Fresh Air Ventilation building code requirements. Some of the applications where HGRH systems are assumed to be preferred include:

- School classrooms and gymnasiums

- Commercial office buildings

- Labs, cleanrooms, etc.

- Any Large Percentage outside air projects

Each one of these systems have their own unique set of challenges that must be addressed either in the design phase or corrected after equipment installation to have a successful project. The biggest challenge is delivering the necessary amount of ventilation air while still maintaining the relative humidity and temperature criteria in the space. But is hot gas reheat the right solution for every application? The short answer is No.

Hot gas reheat limitations

Even with the addition of HGRH in package units, there is still a need for some sensible cooling load in the space to keep the compressor on. Hot Gas Reheat systems are just another way of cooling during part-load operation and will never achieve the same levels of performance as dehumidifiers, as is the common misperception.

One of the major pitfalls of packaged reheat systems is that the reheat coil is much smaller than the evaporator coil. In most cases, the capacity of the reheat coil will only be a third or less when compared to the cooling coil capacity. This capacity mismatch can lead to sub-par performance. The mismatch results in overcooling the space even when reheat coil is active, which will cause the compressor to cycle.

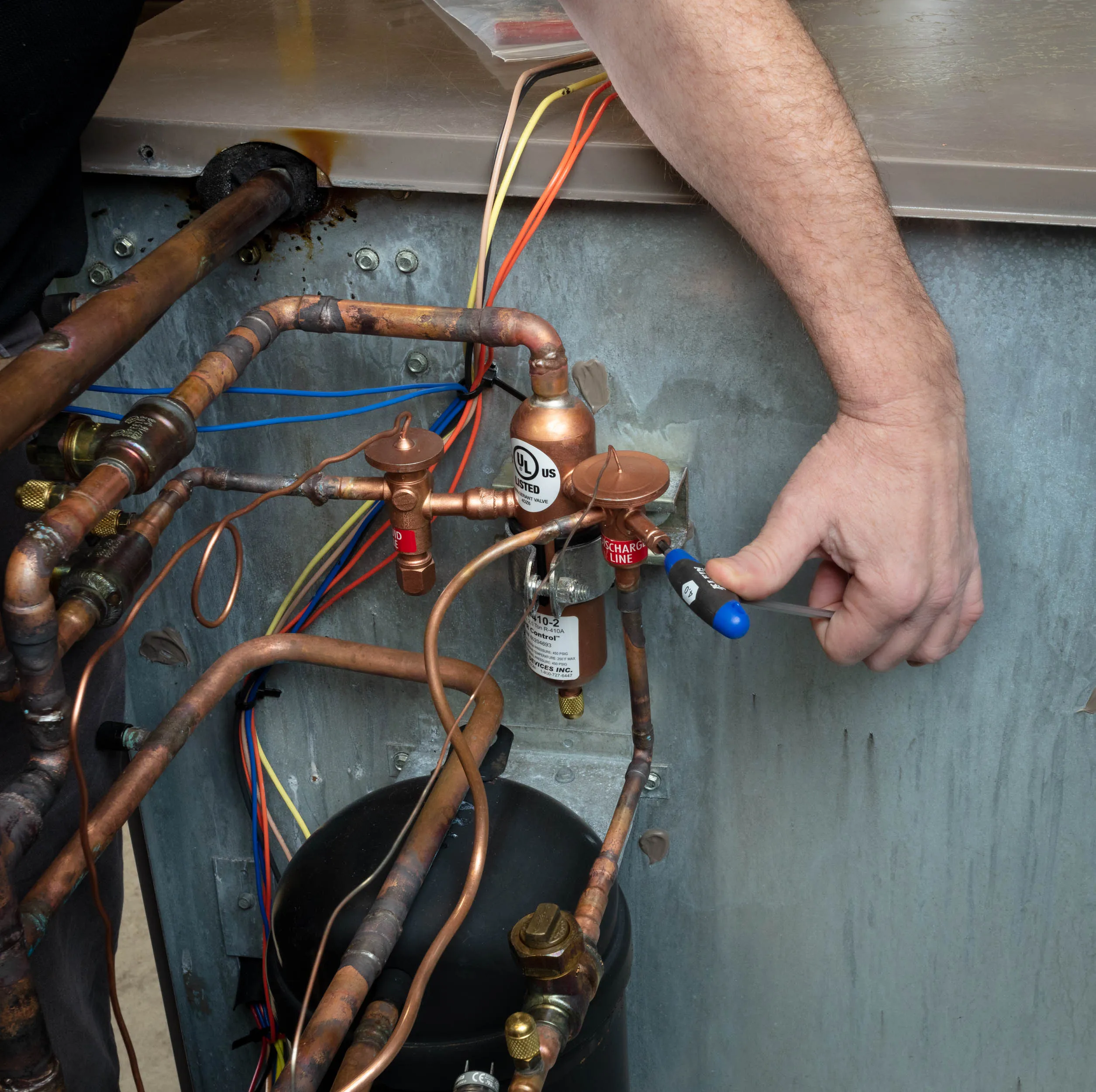

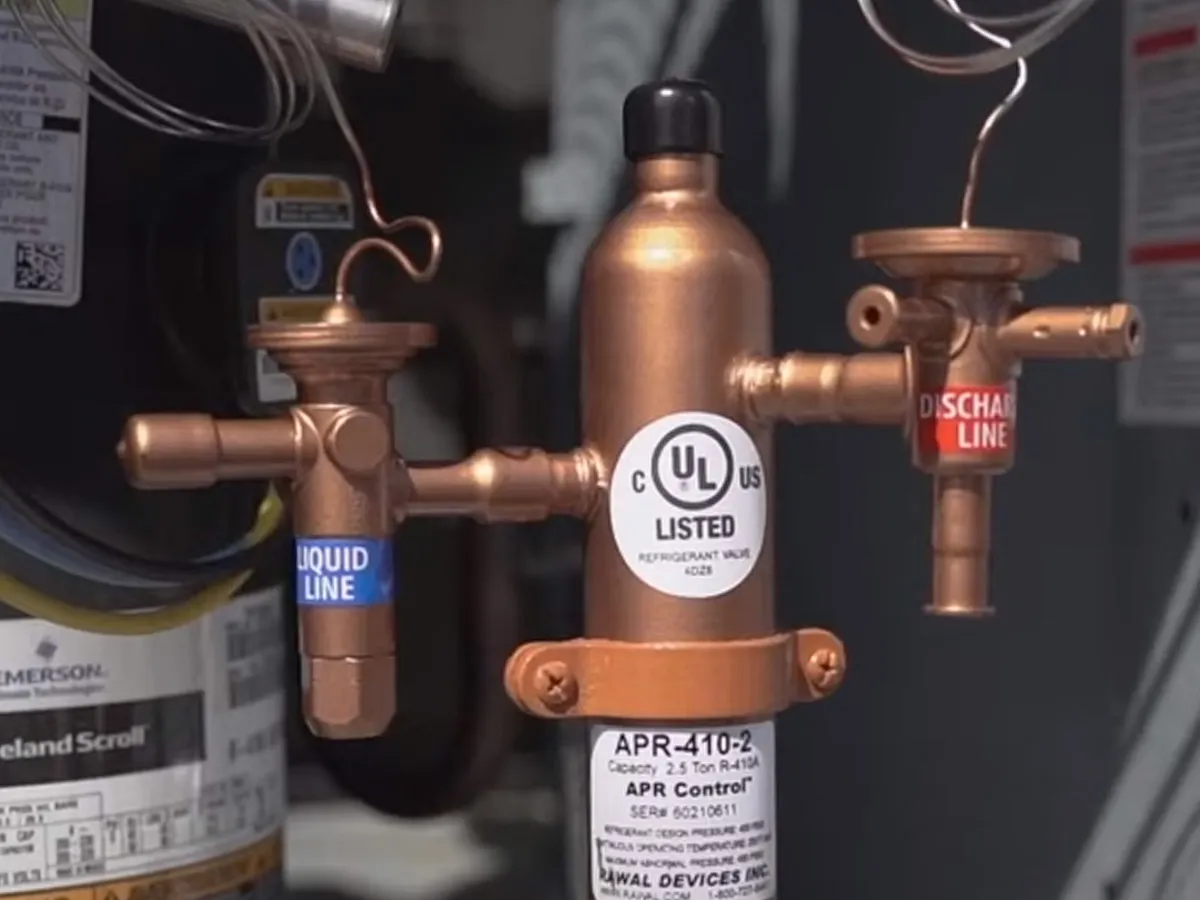

Rawal APR Control offers a solution

Although hot gas reheat has been a common method to achieve design goals including dehumidification and temperature control, the APR Control is often a less expensive preferred design solution. There are plenty of projects that can be successful with just the APR Control’s continuous capacity modulation capabilities. The continuous capacity modulation of the APR Control provides not only the benefits of Hot Gas Reheat but also additional benefits that are not available on HGRH systems!

- Protects the compressor

- Evaporator freeze protection

- Short cycling protection

Instead of reheating the air with hot gas like a reheat coil, the APR Control matches the system’s capacity to the ever-changing load in the space; extending the run-time of the compressor to keep the evaporator coil active and dehumidifying. The APR Control’s capacity modulation allows continuous dehumidification while preventing overcooling of the space. On most applications, the APR Control can provide as much as 80% modulation, which is a larger turndown percentage than standard HGRH. The APR Control provides compressor protection from liquid slugging (floodback) and compressor short cycling. Also, the APR provides evaporator protection from freezing by modulating the capacity in response to a drop in the system’s suction pressure/temperature. The Hot Gas Reheat does not provide any system protection.

Call us today if you’re one of the many who have been pushing off project timelines due to long lead times with hot gas reheat! We are here to help!